Product Description

Overview:

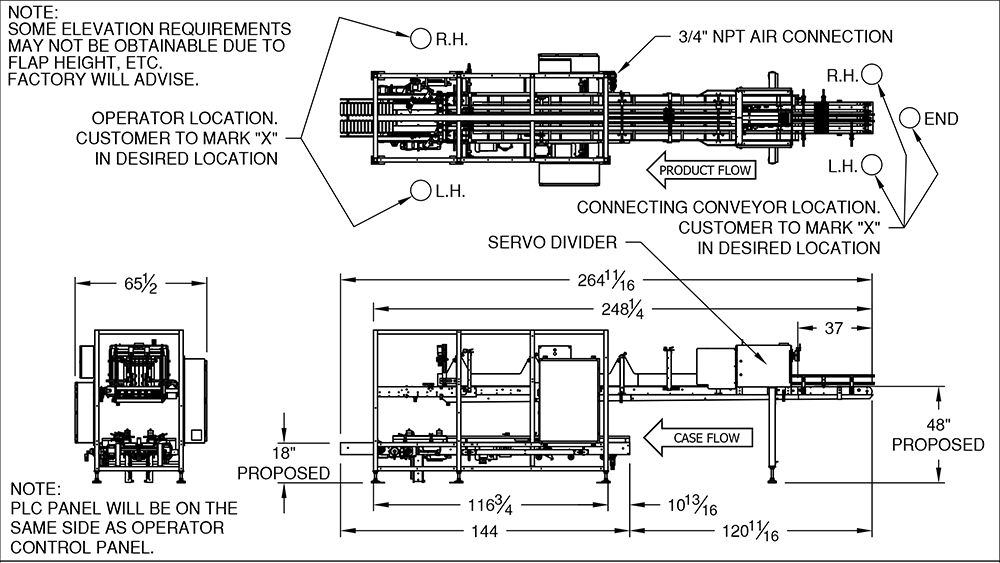

The Hamrick Model 600D-S Case Packer was designed to run round and non-round products in various pack patterns at speeds up to 30+ cases per minute. The product conveyor features an Allen-Bradley Kinetix 300 servo-controlled lane divider to shift product into multiple lanes prior to packing. The case infeed is a servo-controlled lug driven system that allows single or multiple-case per cycle operation. The servo-controlled (rack & pinion) style case lift then raises the case up to meet the custom-designed change parts for that size bottle, and catch-drops the product prior to discharging from the machine. The 600D-S comes standard with a mild-steel, painted frame (Steel-It), along with stainless steel components (lane guides, case covers, drip pans). It can be upgraded to a washdown machine, featuring all stainless steel construction and NEMA 4x sealed electrical panels for washdown or corrosive environments. This machine is designed with the operator in mind, keeping a level of simplicity to match heavy-duty construction. The electrical package includes an Allen-Bradley CompactLogix PLC, PanelView Plus 7 (10″) HMI, and PowerFlex 525 Series drives. This machine comes with a 98.5% efficiency rating and a 1-year manufacturer warranty on all components.

Standard Features Include:

- Acculane II servo-controlled lane divider assembly to run round and non-round product

- Self-aligning stainless steel case guide top plate on case lift

- Servo lug chain infeed to accommodate case widths up to 15″ w/ hand-crank width adjustment

- Rexnord mat top bottle conveyor infeed

- Modifiable infeed rails to perform LH, RH, or end entry product transfer

- Closed cell neoprene shock pad on case lift to reduce drop impact

- Vertically mounted servo-controlled (rack & pinion) style case lift with up to 18” adjustable lift height

- Fixed-position hand-crank overhead bottle brake assembly

- Stainless steel lane guides w/ color-coded spacers for each set of change parts

- Allen-Bradley CompactLogix PLC

- Allen-Bradley PanelView Plus 7 (10″) color HMI

- (2) Allen-Bradley PowerFlex 525 drives

- Pneumatic actuator case brakes for on-demand case indexing

- Easy-access, quick changeover capability

- Fully-enclosed packaging area w/ interlocked safety doors and hinged guards around lane divider

- Steel-It corrosion resistant paint

- Includes one set of change parts + spacers

- Two instruction/part manuals

- One-year warranty

- 100% money back guarantee

Upgrade Options:

- No-tool quick changeover (included)

- Upcharge for non-standard voltage (480V, 575V)

- All Allen-Bradley controls package (included)

- Additional e-stop

- 4-tier beacon (included)

- Down bottle detection (flag system or laser)

- Overhead bottle turners to assist product 90-degrees prior to packing

- Tablock slitter mounted on case lift

- Transport cart & storage racks for easy insertion/removal and housing of packing head assemblies

Reviews

There are no reviews yet.